Contact us

Add: No.11, Tianxian Avenue,

Economic Development Zone,

Tianmen, Hubei, China

Tel: +86-728-5250888

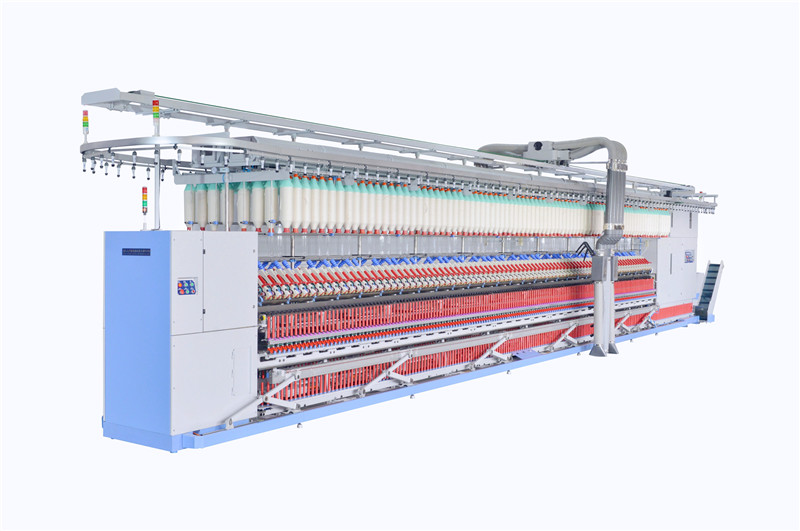

TM5263E Ring Spinning Machine

Brand-new high speed、efficient、energy-saving、digital and intelligent ring spinning machine with auto doffing.

Features:

- The Maximum Spindles of Single Headstock is up to 1632.

Economical, efficient and reliable long single headstock ring spinning machine with auto doffing utilizes the area of factory to the utmost to improve production capacity per unit area and save the cost of production.

- Actual Speed of Spinning is up to 22000 R/M

At the precondition of the quality yarn, less yarn ends and good winding backing-off,the machine equipped with balloon ring runs at a high speed to get higher yield.The actual speed of spinning can keep 22000 R/M.The unique 10 point control ensures the machines are running at the highest speed during the whole spinning process.

-

The Integral Frame,the New Cross Section.

The integral positioning Frame ,the integral wing panel ,each component adopts direct positioning structure to improve the efficiency and precision of installation and ensure the stability at a high speed.

The new cross section improves the yarn quality ,reduces yarn ends and promotes the assembly of compact spinning more flexible.

-

The Intelligent Electronic Lift

Lift of ring plate and yarn guide plate driven by servo motor,setting the parameters of winding and shaping by programming,the intelligent program control make the shaping of spinning more reasonable,the bobbin package larger and are suitable for high speed winding.

-

The Intelligent Electronic Draft

Multiple servo motor separately drive each roller through maintenance-free planetary reducer, all the spinning parameters including twist,draft ratio and rear draft ratio are set up on the display screen,the intelligent program control accomplish the perfect synchronism of draft and twist components,improve precision of draft,and ensure the higher quality yarn and less yarn ends.

All kinds of spinning parameters can be copied and transferred to other machines, to avoid the unreliability because of manual operation, and to ensure the safety in altering batch in a short time.

-

The Intelligent Doffing and Automatic Bobbin Feeding.the Intubation Ratio is up to 100%,3 Minutes Doffing,the Ratio of Ending is up to 98%.

Applying all-around precise light ,electric and magnetism detecting system to ensure reliability and intelligence of doffing,the new buffered grasper can move softly to ensure doffing stabler,reduce the maintenance cost of air frame, the shaped cam stopper ensure the shaped cam always be at the right place.

The accessory automatic bobbin feeding machine saves labour,reduces the labour intensity,entire automatic,trouble-free running,and only one time feeding can meet the need of single doffing.

-

Double-Head Suction and New Energy-Saving Compact Spinning Etc. Save Energy Up to Above 20%.

Double-head suction effectively reduce energy consumption,and balance the negative pressure of machine.

The new pulse gathering compact spinning improves and ensures the quality of gathering as well as effectively reduces energy consumption, substantially saves the running cost of air-conditioner,and extends the lifetime of gridding ring.Cleaning notch reduces daily maintenance cost.Coupling driving structure of compact spinning simplifies and optimizes driving,and lower the cost of investment and running. Module designed compact spinning device can be installed at any time.

-

Innovative Efficient Drafting System.

Breaking through the traditional drafting system, improve the quality of yarn,save the consumption of energy,reduce tear and wear,reduce the consumption of material,save the labour of maintenance ,improve the efficiency of production and management,and lower the investment of pre-spinning equipments.

The unique high-standard special parts are suitable for normal ring spinning,fancy spinning and siro spinning etc. All kinds of high quality yarns can be produced.

-

Single-Spindle Detection, Spindle with Yarn Gripper

Single-spindle detection is used for comprehensive production management and quality control,and all the datas including the ending detection,abnormal detection of spindle,yield statistics and quality monitoring etc.will be displayed on the display screen.

Zero-winding spindle with yarn gripper efficiently improves production efficiency,controls winding of bottom bunching, and doesn’t need the extra cleaning.

-

Combined with Roving Machine and Winding Machine to Improve the Efficiency and Shorten the Running Time.

Combined with the roving machine to convey the roving bobbins automatically.

Combined with the winding machine to convey the ring bobbins automatically.

Including human-machine graphical operation interface and information networking management,and intelligent connection with previous and next process.

Technical Specification of TM5263E Ring Spinning Machine

Number of Spindles:612~1632 (Increasing by every 12 spindles)

Spindle Gauge:70mm

Lift:180mm,200mm

Drafting System:Electronical Drafting,3-row rollers,long and short aprons,cradle weighting.

Lift Type: Electronical lifting

Type of Doffing :Auto doffing

Type of Spindle:Aluminium plug type spindle(yarn gripper Optional)

Spindle Speed:12000~25000RPM

Twist:160~2600T/m

Drafting Ratio:10~120 times

Yarn Count:1.94~96.2tex(6~300Ne.)

Range of Application:100% cotton and blends of cotton,cotton-type chemical fibre

Length of Fiber:Under 40mm,51mm,60mm,65mm

Dia.of Roller:φ27Xφ27Xφ27,φ27Xφ30Xφ27,6 spindles per section

Dia.of Ring Rail:φ38mm,φ40mm,φ42mm,φ45mm

Spindle Drive:4 spindles per group,tin pulley drive,with single tension plate

Twist Direction:Z,S

Type of Brake:Pneumatic disc breaker

Type of Roving Creel :Single 6-rows,single 4-rows,single 8-rows,all can match the manual or auto-cycle traveling block.

Electrical Control:PLC

Power of Main Suction Blower:1.5kw X 2(1008 spindle),2.2kw X 2(1200 spindle),3kw X 2(1632 spindle)

Power of Main Motor :37kw(1008 spindle),45kw(1200 spindle),55kw(1632 spindle)

Type of Compact Spinning:4 rollers,web ring,pluse gathering suction,coupling drive

Power of Compact Spinning Suction Blower:11kw(1008,1200 spindle,siro spinning),15kw(1632 spindle,siro spinning )

Single-Spindle Measurement:(Optional)

Roving and Spinning Combination,Spinning and Winding Combination :(Optional)

Product components:

Home

Home